June 2, 2018

Creating a minimal iPhone stand

Routing oak wood for a custom fit

Today I created a minimal iPhone stand from oak wood. While it's much faster to buy one online, I wanted one to fit my phone horizontally, with its case on. I like minimal design, so I opted to machine a single piece of wood to get it done.

Need for an horizontal stand

I use my smartphone in combination with a bluetooth keyboard to get serious work done using just my phone (writing, server management over SSH, even programming using VIM). The keyboard is really great, but the combination keyboard+smartphone is even better with a decent stand (for a better angle).

I use most apps in horizontal or landscape mode. The stand must allow the phone to be picked up easily (to change display orientation, take photos or walk away). Although I use a very common iPhone X, I do use a case that is slightly thicker than most: it doubles as wallet.

Preferably I wanted a minimal stand, made from one single piece, with no moving parts - but as compact as possible for easy transport (on my bike, the train, plane, etc). I like "raw materials", preferably without paint or lacquer.

Prototyping

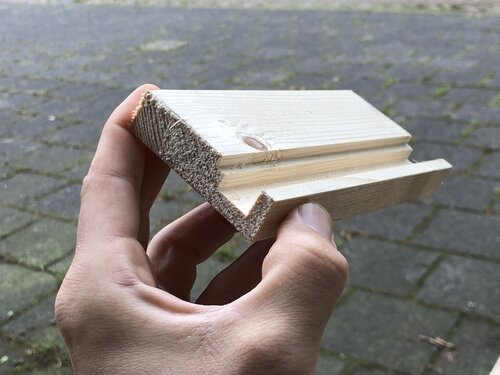

The software engineer in me decided it was a good idea to develop a prototype using spruce wood. This is a very light type of wood that is easy to machine. I picked up some leftover wood from the local do-it-yourself store and determined the right size and profile for my phone to fit.

Because my smartphone with its case is slightly thicker, I needed a wider profile to arrange a secure fit. The "stair like" side in the profile allows the phone to fit with a nice angle. Finding the right profile was a matter of trial and error, making minor adjustments to improve fit and angle.

Final version from oak

Once I was satisfied with the prototype, it was time for the final version. For this I selected a different kind of wood: oak. This is much harder, heavier and therefore durable. Its more difficult to machine, but having learned from my prototype I could skip testing and go straight to the right fit.

To give the stand a friendly and high-end feel, I used a special router piece for rounding the edges.

Just like the outer edges, I machined the inner ridge with an inverted round routing piece for better looks (and softer feel to the fingers).

During my work on the final version I regularly checked the prototype to ensure a proper fit.

After completing the wood routing I tested the final version. Although both versions where functionally the same, they feel different. It's amazing how much of a difference the kind of wood makes in feel; the oak feels like it will outlast the phone like a thousand times.

Finishing touch

Using fine grained sanding paper I finished the surface of the wood. I went from paper 80 all the way up to grain size 400. Its really surprising how silky smooth the wood becomes.

Conclusion

After some hours of wood working fun, I got myself a perfect fitting wooden iPhone stand.

Although its much faster to buy a stand, there is something strangely rewarding in doing it yourself. You learn to machine and to handle raw materials. You never know when these skills become handy in the future!